Our projects

Conveyor belt closure works – Taranto (TA)

Client

Profilglass

Task performed (2025):

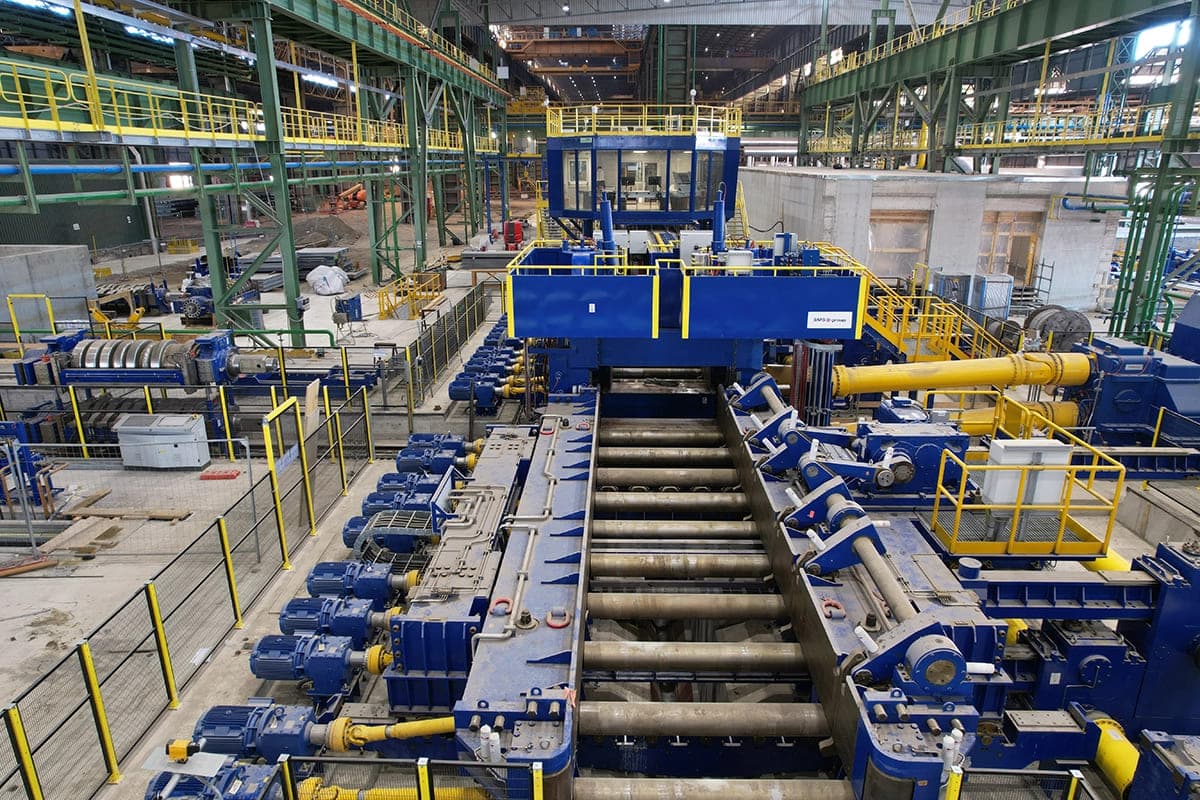

Construction of a new Hot-Rolling plant – VA 750

Description of processing phases: For this job, we are installing and assembling from scratch:

- Heating furnaces: furnaces are installed that heat the materials up to the rolling temperature;

- Rolling mills: the rolling mills are assembled, consisting of pairs of rollers that reduce the thickness of the material;

- Transport systems: conveyor belts, rollers and other systems are installed to move materials within the plant;

- Cooling systems: systems are installed to cool the rolled products, such as cooling tanks or air cooling systems;

- Sistemi di controllo:Control systems: automatic control systems are installed to monitor and regulate the rolling process.per monitorare e regolare il processo di laminazione.

Hot-Rolling plant – Fano (PU)

Client

ArcelorMittal Italy (formerly ILVA)

Task performed (2020)

Closure of material conveyor belts

Naval unloader assembly work

Client:

SIWERTELL (SWEDEN)

Assignment performed (2018): Manufacture and perfom assembly work of steel and perform electrical and mechanical assembly of supplied equipment forn SIWERTELL’s ship unloder project 7/17NT03 YARA 2 (NORWAY)